© 2018 Zhangjiagang YUSHENG MachineryAll rights reserved. Site Map Designed by iwonder.cn

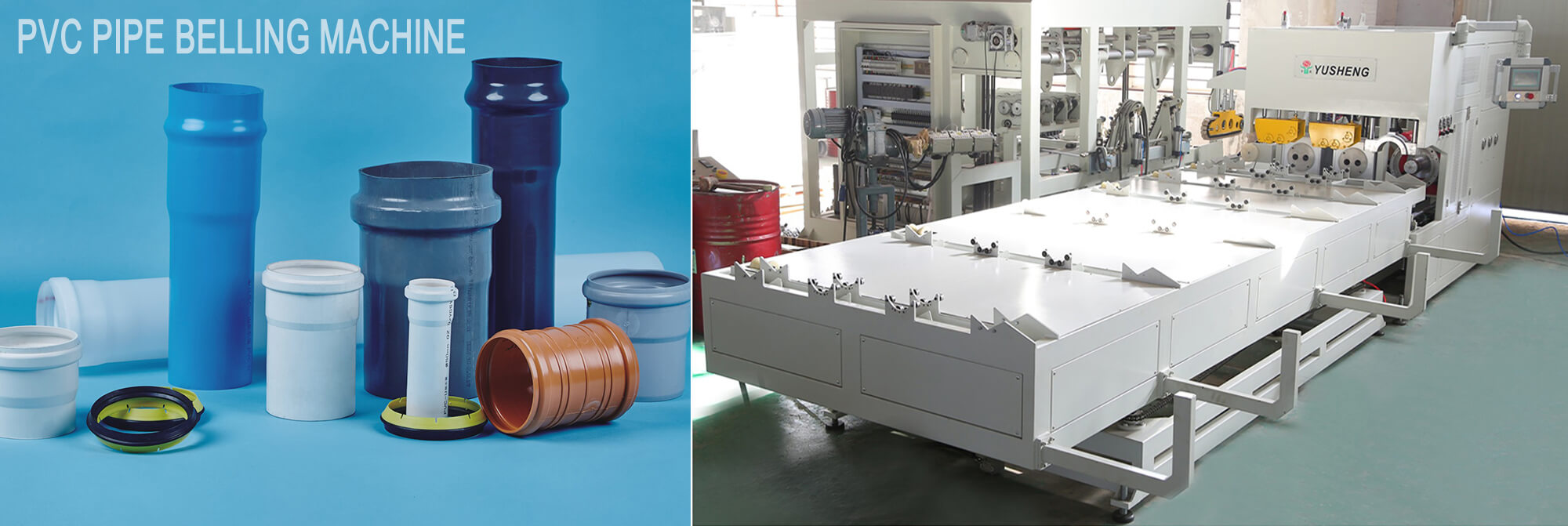

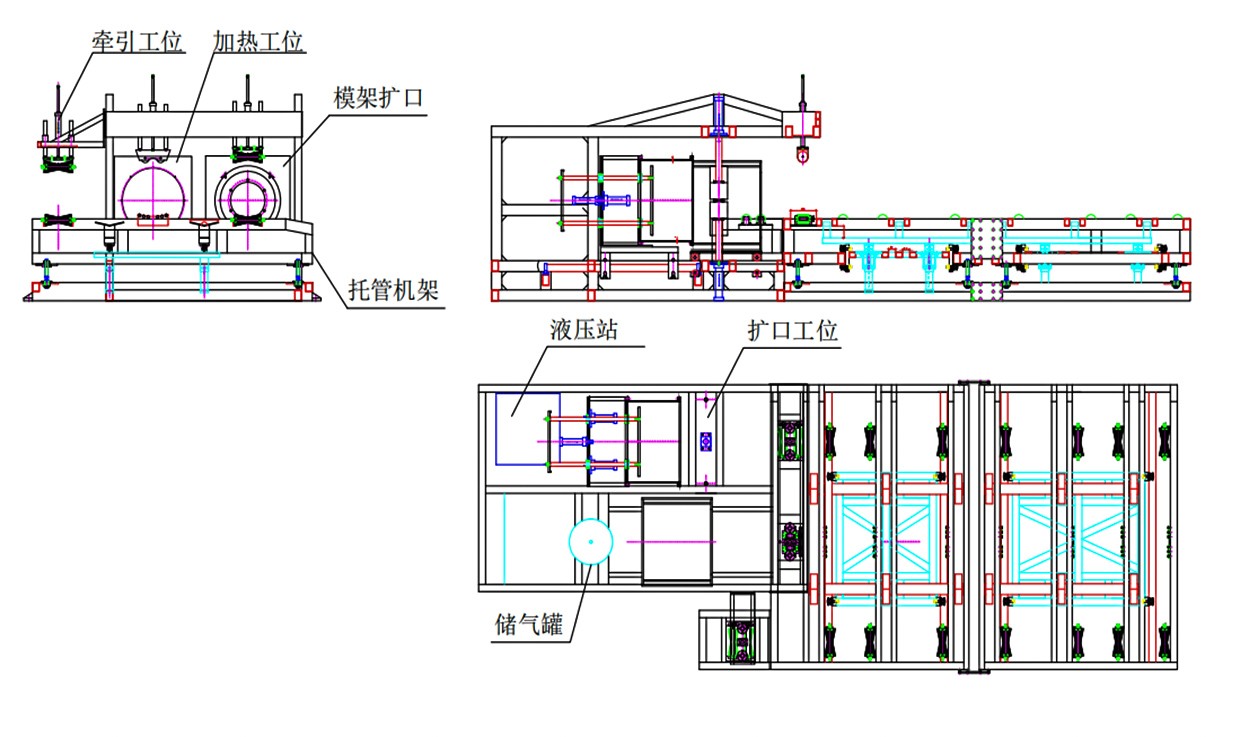

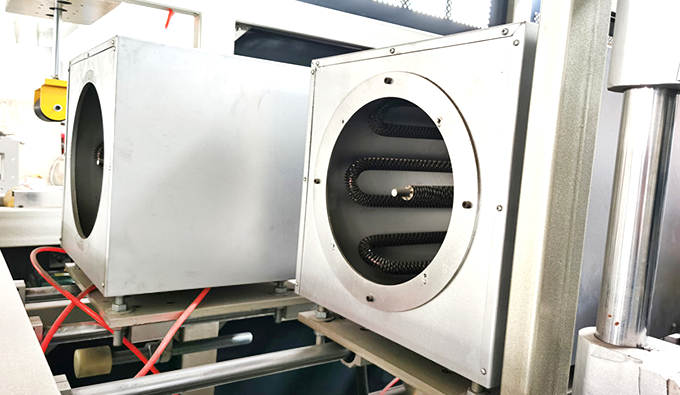

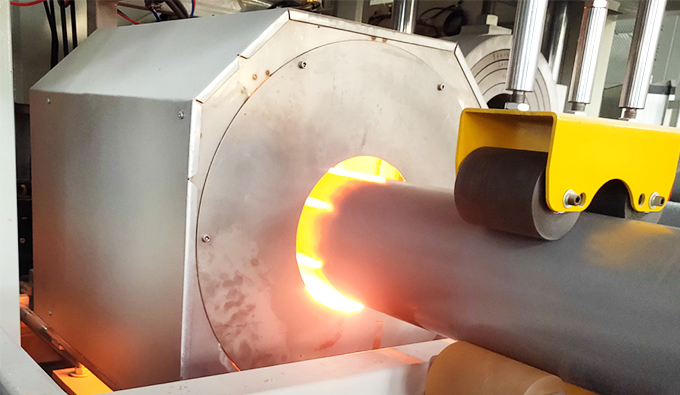

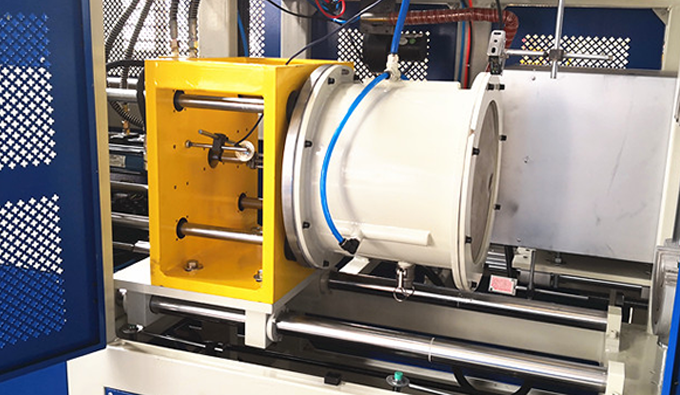

The pvc pipe belling machine consists of three parts: pipe traction part, heating oven, socket making part.

Full automatic belling machine can improve the working efficiency and at the same time liberates the human resource.

With the international electrical brands such as Siemens, Schneider, Omron and Autonics, the operation of the complete machine is easy and stable.

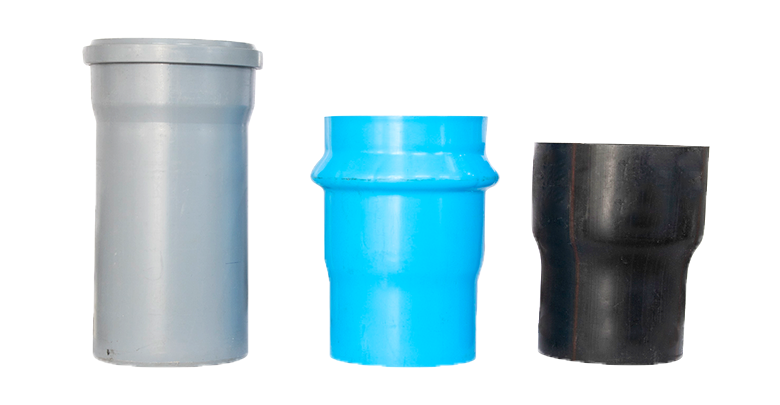

The machine is mainly use to make socket for pvc, pp pipes. Have different socket functions, such solvent cement type, rubber ring type and Z type.